Summary

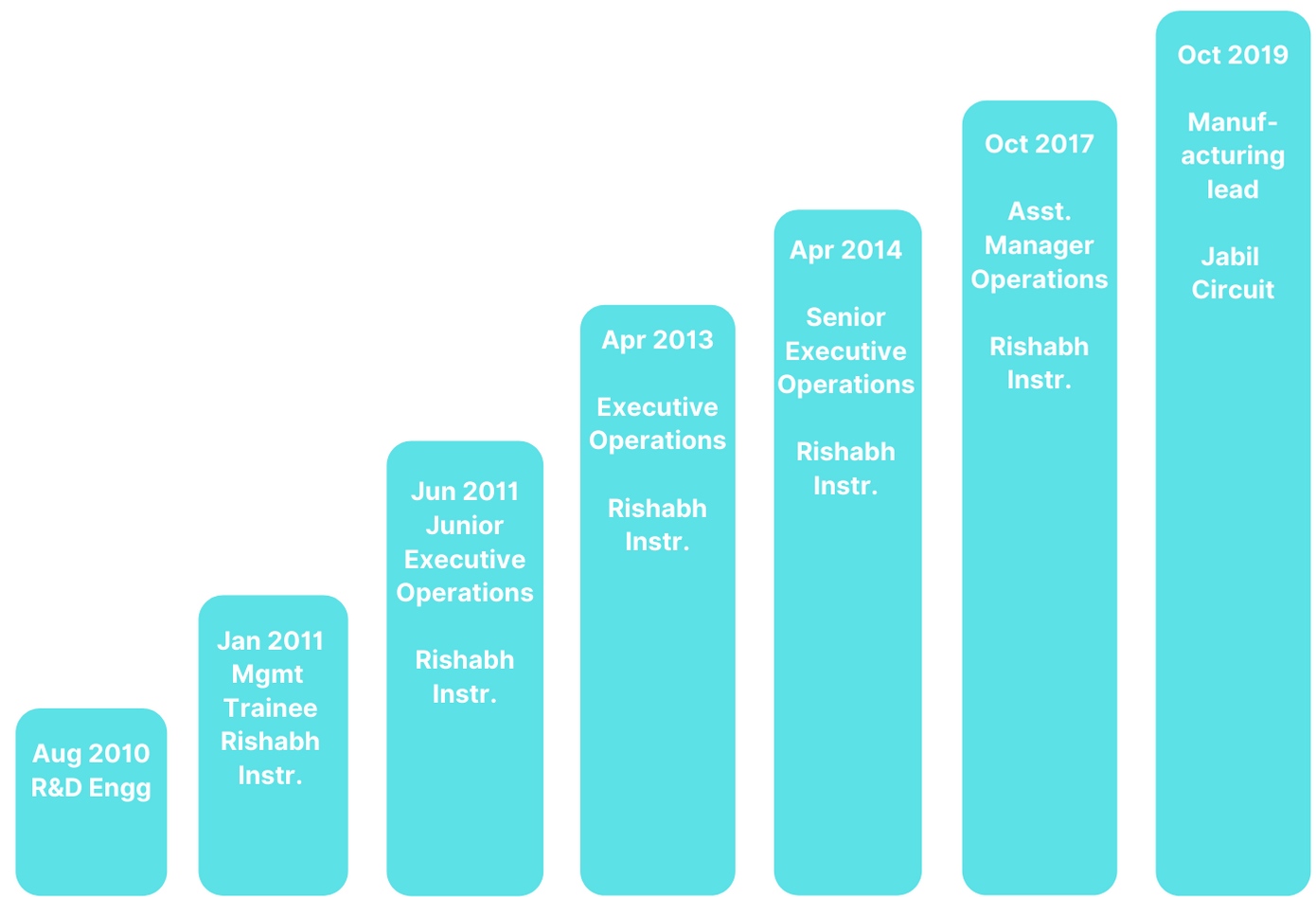

Career Graph

Experience

Jabil Circuit Pvt. Ltd.

Oct 2019 - Till date

Manufacturing Lead

Manufacturing Lead for a Consumer Electronics Manufacturing Business Unit

Responsible for production of consumer electronics devices for an American client contributing to USD 1.8 Million (INR 13 Crores) Monthly revenue.

Rishabh Instruments Pvt. Ltd.

Jan 2011 - Sept 2019

Brains Innovations

Aug 2010 - Dec 2010

Trainings

Awards

Education

Post Graduate Diploma in Business Administration - Operations

Symbiosis Center for Distance Learning

Secured First Class

Bachelor of Engineering - Electronics

University of Pune

Secured First Class with Distinction

Skills

Manufacturing Operation Skills

Manufacturing Quality Skills

Computer/ERP Skills

Personal Skills